Using accumulated rich technology and experience, provide products that meet customer needs.

Wire

Stainless steel wire is made from hot-rolled coils and undergoes repeated heat treatment and cold drawing processes as needed to achieve the desired size and smoothness.

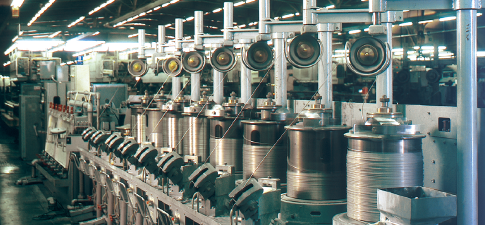

Fine wire drawing

Drawing is the process of using a mold to pull wire to obtain the desired size and hardness. There are two types of wire drawing: dry method, which uses powder lubricant to pull the wire through the mold; Wet method, using oil-based lubricants.

Burn pure

Annealing is performed in the previous process to eliminate hardening during wire processing and to uniformly soften the wire.

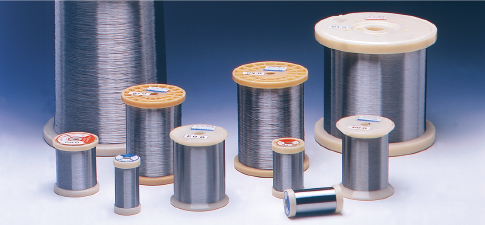

Roll into a tube

Thin and ultra-fine wires of 0.5 millimeters or smaller are wound and transported on a wire shaft. Wire spools are classified into various types based on their usage, ranging from a small amount of 100g to a large amount of 25kg depending on the wire diameter.

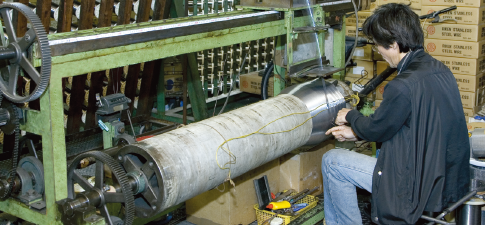

Warping

The manufacturing of wire mesh begins with warping. For warp knitting, considering the type, composition, and yield of woven metal wire mesh, the metal wire is wound from the spool onto the drum.

Wearing steel reeds

The warped vertical lines pass through the spring holes on the drum one by one. The type of metal spring used is determined by the vertical mesh and wire diameter. Each metal spring has a precise and regular comb shape, and each vertical wire passes through this space one by one.

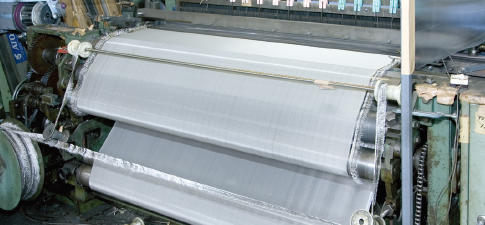

spinning and weaving

Stretch the vertical thread and weave the horizontal thread through the diagonal opening of the vertical thread.

Inspect packaging

The woven wire mesh is inspected and tested, then packaged and shipped domestically and internationally.